The rise of digital technologies has been a game-changer across various industries, and inventory management is no exception. With automation and analytics, businesses can optimize their inventory management processes, transition from manual struggles to operational excellence, and maximize profitability.

This article explores how inventory planning software can streamline your operations, the key issues related to inventory management, and how automation can help overcome these challenges.

The Evolution of Inventory Management:

Inventory management has come a long way, from manual, paper-based methods to advanced digital and automated platforms. The shift has brought:

-

Faster, more accurate forecasting.

-

Reduced human error.

-

Improved operational efficiency.

Q: Why is digital transformation critical in inventory management?

Because it eliminates inefficiencies, reduces mistakes, and provides real-time insights that manual systems simply can’t match.

The Key Challenges in Inventory Management:

Managing inventory is more than just stocking products. It requires balancing multiple factors:

-

Overstocking or understocking → Leads to tied-up capital or missed sales.

-

Inaccurate forecasting → Causes gaps in supply and customer dissatisfaction.

-

Supplier management → Delivery delays can disrupt production.

-

Complex logistics → Tracking routes and warehouse activity across locations.

These pain points create ripple effects across the business - lost sales, higher costs, and frustrated customers.

The Role of Inventory Planning Software in Optimizing Inventory Management

Inventory planning software tackles these challenges with machine learning, predictive analytics, and automation. Instead of replacing existing ERP or CMS systems, it works alongside them, focusing on forecasting, planning, and optimization.

Key capabilities include:

-

Accurate demand forecasting using historical data and AI models.

-

Optimal stock levels to balance customer demand with working capital.

-

Supplier management tools to strengthen vendor relationships.

-

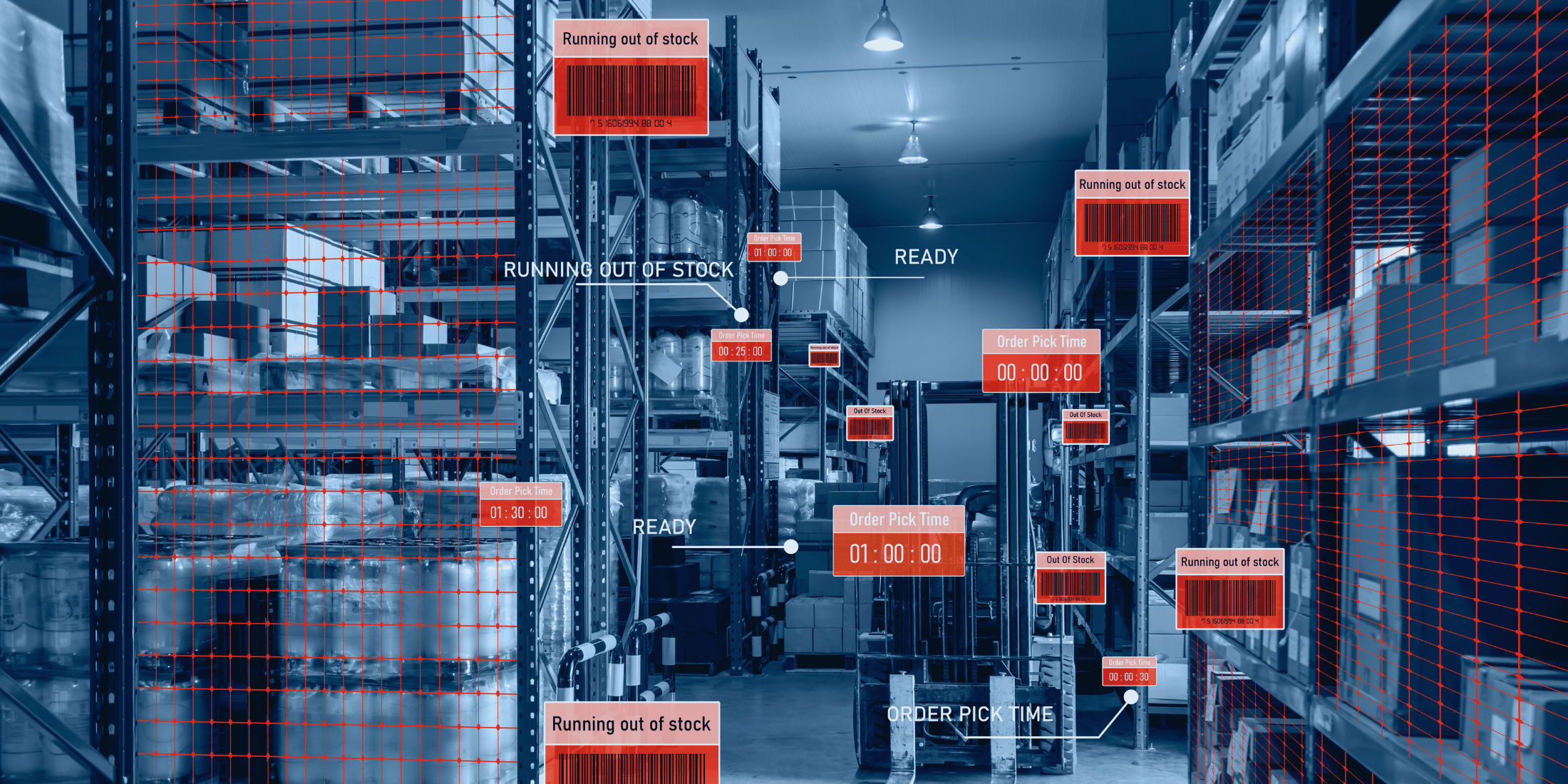

Real-time inventory tracking across warehouses and channels.

Q: Does inventory planning software replace ERP systems?

No, it enhances them by adding forecasting and planning capabilities without disrupting existing workflows.

From Manual Struggles to Operational Excellence

Shifting from spreadsheets and guesswork to automation delivers measurable improvements:

-

Efficiency → Automates repetitive tasks.

-

Accuracy → Reduces human error.

-

Speed → Decisions are made in real time.

Automation and analytics complement each other: automation boosts efficiency, while analytics powers smarter, data-driven decision-making.

Benefits of Automation for Inventory Optimization

Businesses adopting automation gain a competitive edge. Some of the most impactful benefits include:

-

Improved Forecasting – Uses predictive analytics to reduce overstocking and understocking.

-

Efficient Stock Management – Maintains just the right amount of inventory.

-

Stronger Supplier Management – Tracks delivery performance and reduces disruptions.

-

Smarter Decisions – Real-time insights enable agile responses to demand shifts.

The Integration of Inventory Planning Software

Inventory planning software can seamlessly integrate with your existing CMS or ERP, enhancing their functionality without disrupting your current workflows. This smooth integration allows businesses to implement advanced inventory management techniques without requiring substantial system overhaul or excessive staff retraining.

Facilitated Real-Time Tracking

For e-commerce, retail, and multi-warehouse operations, real-time visibility is critical. Automated systems keep inventory data updated instantly, reducing discrepancies and ensuring accuracy.

This means businesses can:

-

Prevent overselling or underselling.

-

Synchronize data across warehouses and sales channels.

-

Quickly adjust to demand spikes or supply chain issues.

Enhancing Supplier Relationship Management

Automation doesn’t just improve internal processes—it strengthens external ones too.

-

Monitor supplier performance.

-

Track delivery times and consistency.

-

Evaluate quality and reliability.

With data-driven insights, businesses can negotiate better terms, minimize risks, and build long-term supplier partnerships.

Transforming the Supply Chain with Automation

The supply chain is often the most fragile part of a business. By integrating automation, companies can:

-

Detect bottlenecks.

-

Predict potential disruptions.

-

Optimize logistics in real time.

Inventory planning software turns the supply chain into a proactive, efficient, and resilient ecosystem.

The Power of Cloud-Based Inventory Planning Software

Cloud-based systems bring agility and scalability to inventory management:

-

Anytime, anywhere access to data.

-

Scalable infrastructure that grows with your business.

-

Built-in collaboration for teams and stakeholders.

-

Stronger data security with encryption and automated backups.

Empowering Businesses with Data-Driven Decisions

Data is the new currency in business. With advanced analytics, companies can:

-

Predict trends with accuracy.

-

Understand customer behavior.

-

Optimize operational performance.

Q: Why is data-driven inventory planning more effective than manual methods?

Because it relies on evidence, not guesswork, enabling smarter, faster, and more profitable decisions.

Ensuring Business Continuity with Automated Inventory Management

When disruptions occur—whether due to demand spikes, supply delays, or market shifts—automated systems provide resilience.

They help businesses:

-

React quickly to changes.

-

Maintain service levels.

-

Continue growing even during crises.

Streamlining Audit and Compliance

Compliance and audits are far easier with automated systems. Instead of manual logs, businesses gain:

-

Accurate, up-to-date transaction records.

-

Fast, report-ready data for auditors.

-

Transparency across the supply chain.

This not only ensures compliance but also highlights areas for performance improvement.

Enhancing Customer Satisfaction

At its core, inventory management is about meeting customer demand consistently. With automation, businesses can:

-

Prevent stock-outs.

-

Reduce wait times.

-

Anticipate needs with smarter forecasting.

This leads to happier customers, stronger loyalty, and increased profitability.

The Path to Sustainable Growth

Optimized inventory management fuels long-term business success by combining automation, analytics, and customer focus.

The results:

-

Lower costs.

-

Higher efficiency.

-

Stronger supplier relationships.

-

Better customer experiences.

Businesses that embrace this transformation gain the agility and insight needed to thrive in today’s competitive landscape.